Geoff Winder’s been hard at work in the Esprit VQ Garage during the break, playing with 3D printing to make parts for his Esprit. Enjoy this story from the garage, which recounts a mission to make a 3D-printed tailgate hatch opener, with thanks to Geoff.

Don’t Sweat the Little Things

Geoff Winder

More fun from the Esprit VQ garage.

Well it may be said, ‘Don’t sweat the little things’. After doing battle for the last 6 months with our house’s development application, I really wasn’t in the mood to get up to my armpits in Esprit VQ throttle mechanism (a story for another day.) The council just couldn’t understand why I MUST have 200 square meters of garage! Needless to say, they won the argument.

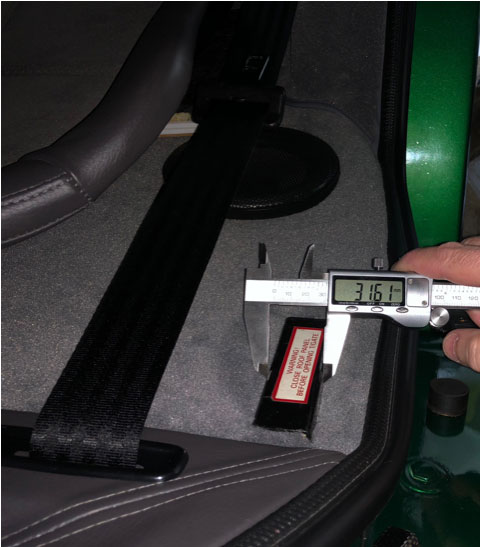

So, I decided to ease in with a fun project. The Esprit rear tailgate is opened with a leaver placed just behind the driver’s left shoulder shown here.

When trimming the car, we cut a hole in the carpet and left it pretty much as is. Lotus use a vacuum-formed bezel that was broken when I received the car. It is really quite cheep and nasty (shown above). I wanted to do something a bit different with carbon fibre.

Last year the girls gave me a 3D printer for my birthday, which has been a lot of fun (and frustration). My plan was to use the 3D printed bezel as a buck for the eventual carbon moulding.

I have long since installed an electric hatch opener (I still wanted the manual pull handle as a backup) and electric petrol flap releases in the car. So this was my initial prototype.

With the proof of concept sorted. I finalised the drawings in Fusion 360 and was ready. As you can see I decided to include a switch for the eventual electrification of the front bonnet.

At this stage I started to entertain the idea of simply making the item from the 3D print and installing it without the need to go to carbon. The only concern is that PLA, the beginner’s plastic of choice for 3D printing, is not really suitable for environments over 60C, as it can soften and warp. I figure a hot Sydney day with the part in direct sunlight and its surface temperature will easily get there. So, I purchased a roll of ASA, which is a slightly more print-friendly version of ABS, suitable for temps up to 110C. I read up on suggestions and tips on the web and set the 14 hours to print.

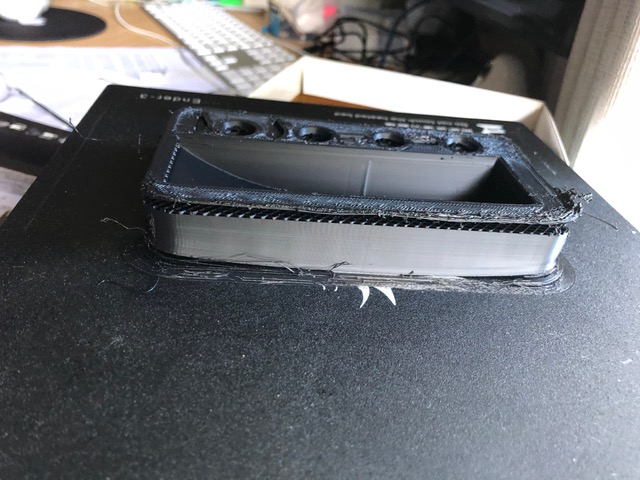

The first picture, my first print with ASA, is the best result I have had. The whole printer was placed in a box with blankets to keep the heat in (and a smoke detector on top). The bed was set at 100 deg C. However, the next morning I has greeted with this mess.

The following morning after some modifications to the design and printer settings. I was greeted with a pile of spaghetti and the build plate, with print still attached, was forcibly ejected from the print platform. Due to more warping in the print.

After two more exercises in creating scrap plastic. I decided that perhaps ASA was just not something I was going to master with this design and my printer. I have purchased some PET-G, which is supposedly much easier to print than ASA but can handle temps of over 80 Deg C.

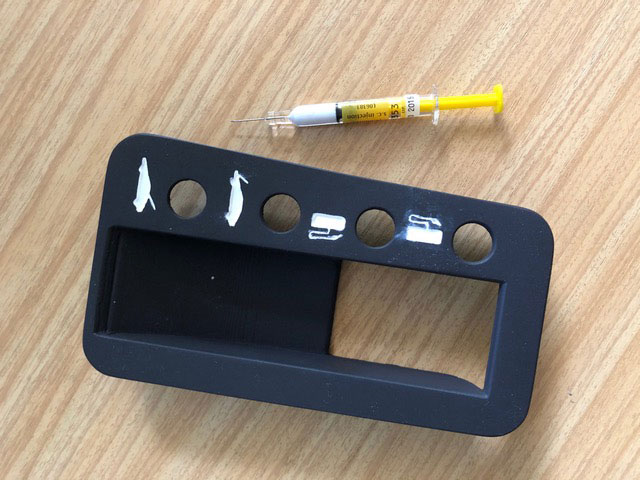

However, I couldn’t wait for the delivery so I went ahead and printed a PLA version of the final model which came out perfectly. After a gentle sand and paint (with vinyl paint left over from some other interior parts and matched to the leather colour) I was left with this.

Since I have come this far I will install this version and see how it survives. Lets face it, my cars don’t get exposed to full sun very often and if it does bend, well I still have the drawings and printer.

With switches

The original plan was to back light the graphics, but I decided that was probably a bit over the top.

So, I settled for white acrylic paint. Yes this means my secret life of paint injecting is now public knowledge, but in the interest of art I must share… As you can see by the 4th injection I am starting to get a bit wobbly.

All tidied up now and ready for final assembly and installation.

Sorted!

One Comment on “Don’t Sweat the Little Things: Fun in the Esprit VQ Garage with Geoff Winder”

Hi Geoff, great work, looks very neat and professional.