Club Lotus Australia is full of interesting people who are up to interesting things with interesting cars. We think that’s wonderful, so we’re going to share their stories with you here!

If you’d like to share your story on the club website, just send Seth a quick email at [email protected]

Last time we met Geoff Winder, he was fabricating and wrestling the sump into his Lotus Esprit VQ. In this post, we rejoin Geoff as he fabricates an inlet manifold to fit under the bonnet of the Esprit VQ.

Read Part 1 here.

Read Part 2 here.

Read Part 3 here.

Read Part 4 here.

By Geoff Winder

This is one of those times when you have a problem and you just fix it. In hindsight I should have just put in a bonnet bulge and called it a day.

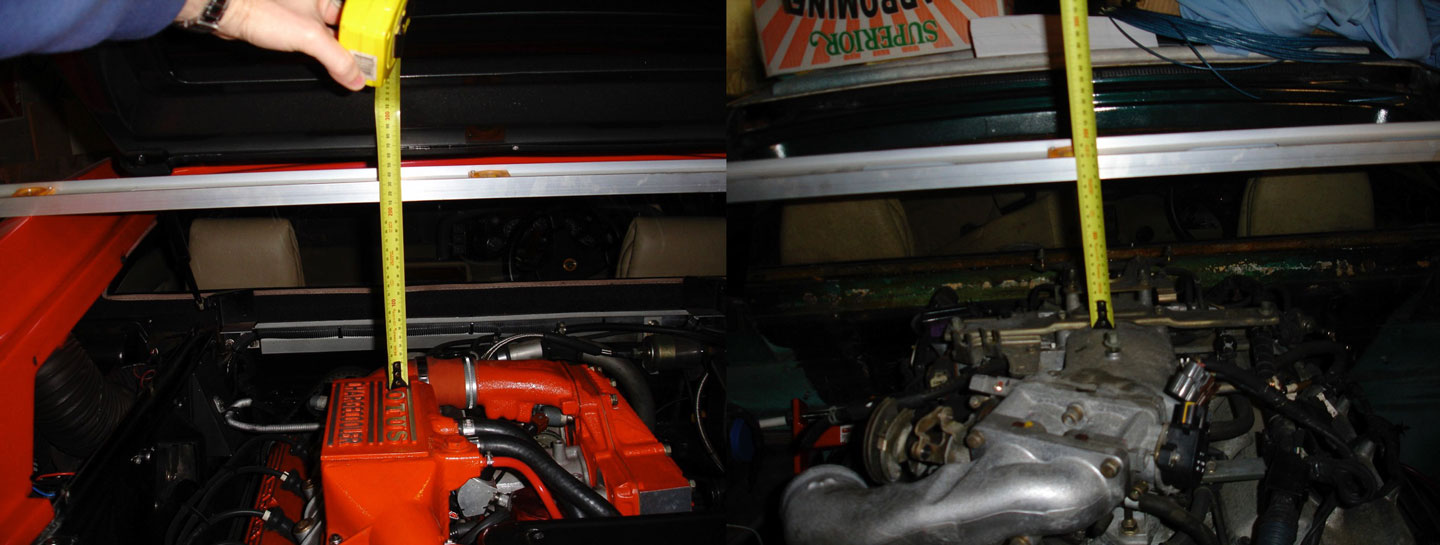

Here is the engine clearance on the right the VQ and the left the factory engine clearance.

As you can see I had to lose about 50mm of the height of the inlet manifold. So, fresh from my expert (cough) welding on the sump, I decided I was up for more.

I found a couple of old Apple computer cases in the rubbish – recycle time.

Annealing a PowerMac cover:

- Rub a soap bar across the top of the cover

- Make sure She is out

- Place on BBQ and wait until soap turns black

- Remove and cool slowly.

Apparently this also works for aluminium 🙂

Bolt between pipes and bend.

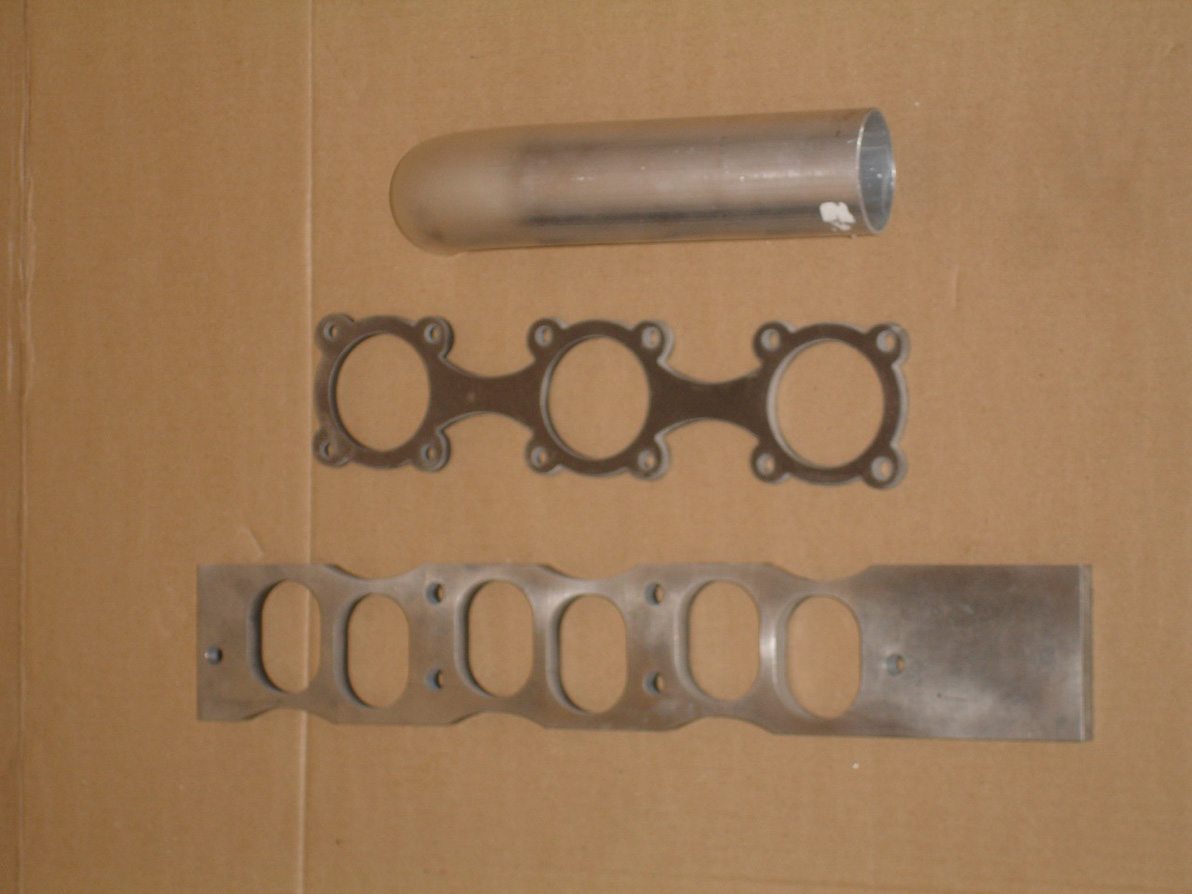

I love getting things from the Water Cutters.

Now polished

Do you see where I am going with this?

How about now?

And it is 50mm shorter!

Trumpets anyone? I can’t spin metal, but I can bash it in a mandrel.

Don’t look to closely at the welding. All I can say is WHAT THE ______WAS I THINKING!

That poor overworked mill!

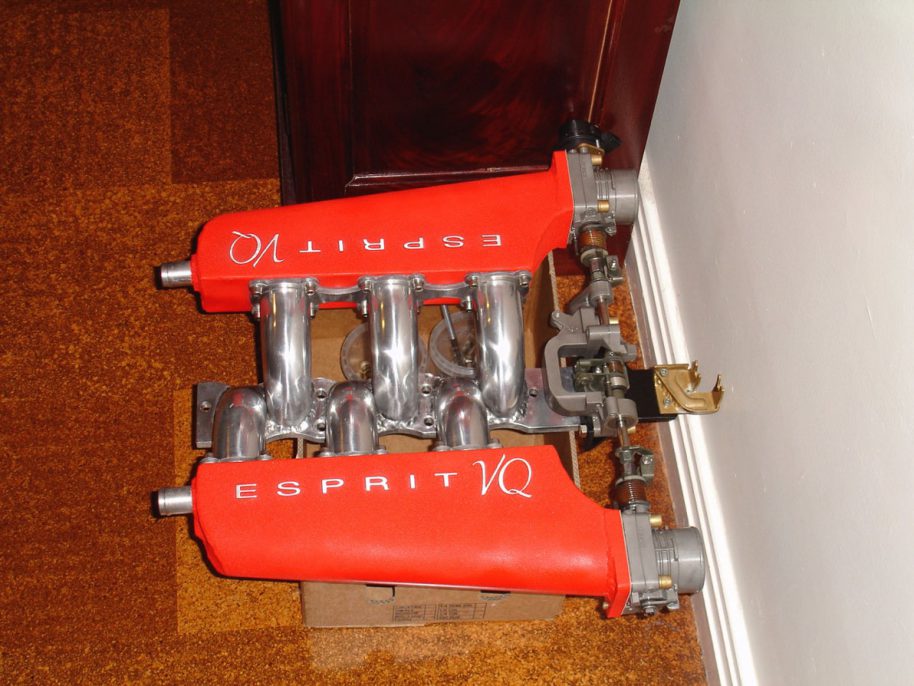

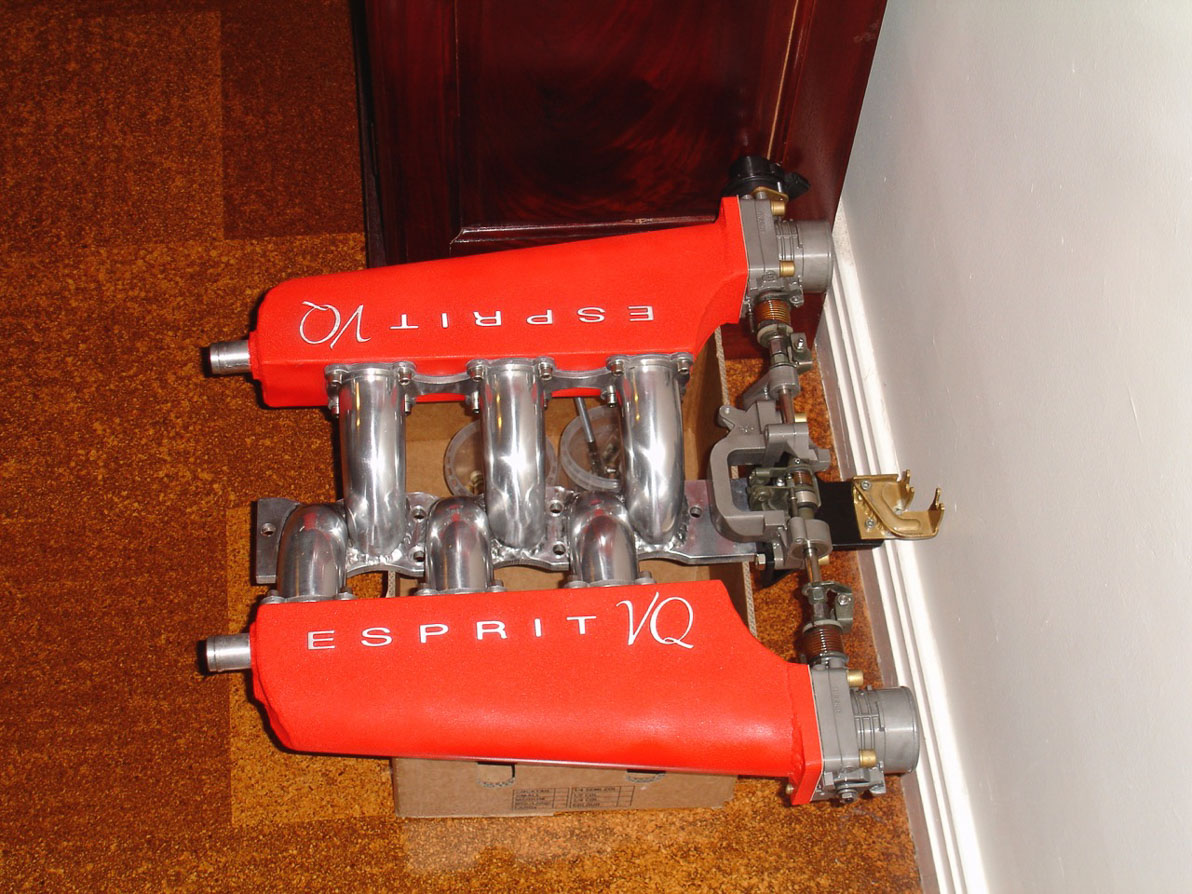

Concept seems to work. Next sort out the throttle bodies and finish plumbing the dozen vacuum lines and the like.

Starting to play with the idea of some letters. Really focusing on the important things now.

Another delivery from the water cutters. What is an “ESPTRI”? I had hoped to have the letters a bit smaller but they said my CAD drawing was too small for their machine’s resolution.

Pretty red!

I am using Nissan 300ZX throttle bodies. I need to adapt the throttle position switch from the VQ throttle body to the 300ZX setup.

Finished.

Bolted on engine with hatch closed. Not a lot of clearance but it won’t hit.

Stay tuned for part 6!